Robolaser

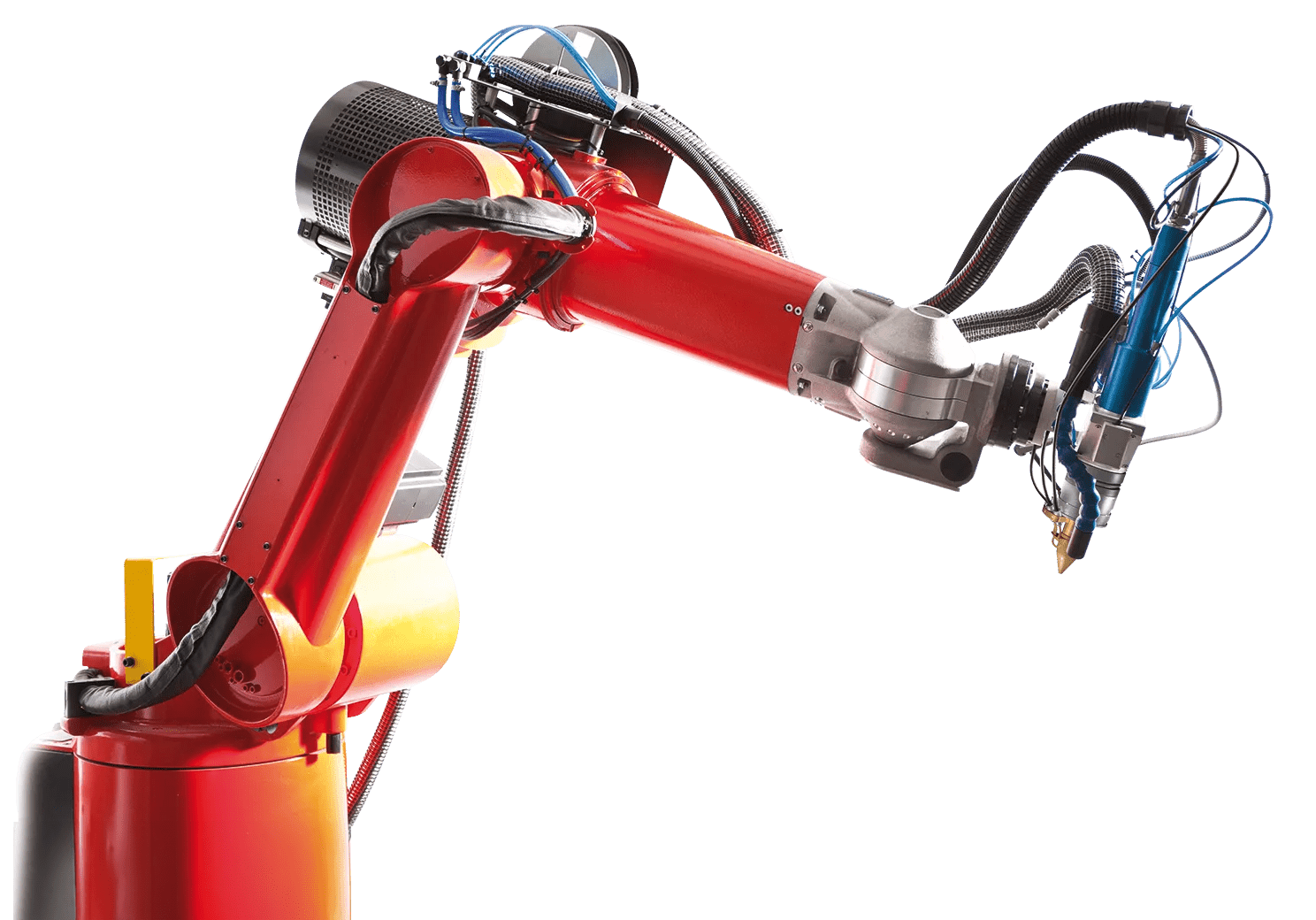

As part of our welding and cladding services, we utilize advanced ROBOLASER technology – Additive Manufacturing. This system integrates the powerful capability of an industrial robot with a 2 kW Fiber Laser source and interchangeable process heads. Furthermore, it is supported by integrated CAD/CAM software. This unique combination allows us to

Robolaser

Additive Manufacturing – about the process

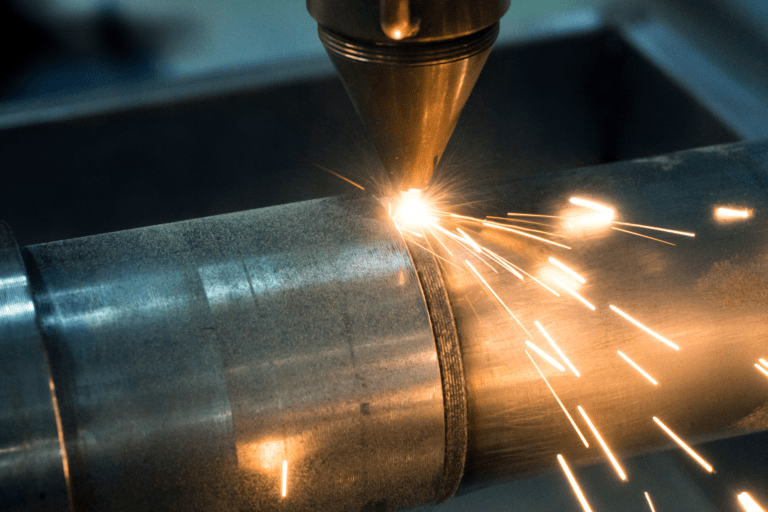

The fiber optic laser with OR Laser scanning head is the ideal solution for widening the welding track width. Fiber Lasers ranging from 0.5 kW to 8.0 kW generate a laser beam size of 50 – 100 microns. The scanner allows widening the spot size up to 25 millimeters.

Laser devices work perfectly when driven by Fanuc robots.

By using ROBOLASER technology, we successfully perform joint welding without material, or with the addition of metallic powder or wire.

-

01.Device power: 2 kW.

-

02.Professional control system for 8-axis robots.

-

03.Integrated CAD/CAM software enhancing device efficiency.

-

04.Fast and professional execution of orders, short, long series, and prototypes.

-

05.High precision in provided services.

ADDITIVE MANUFACTURING SERVICES

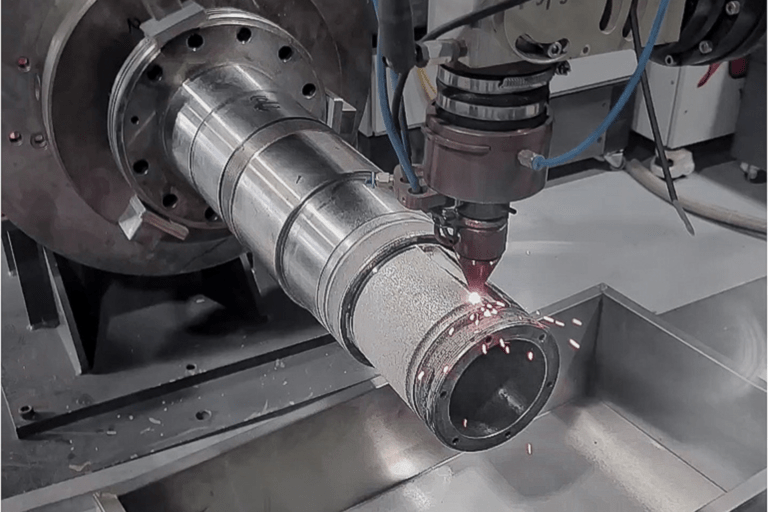

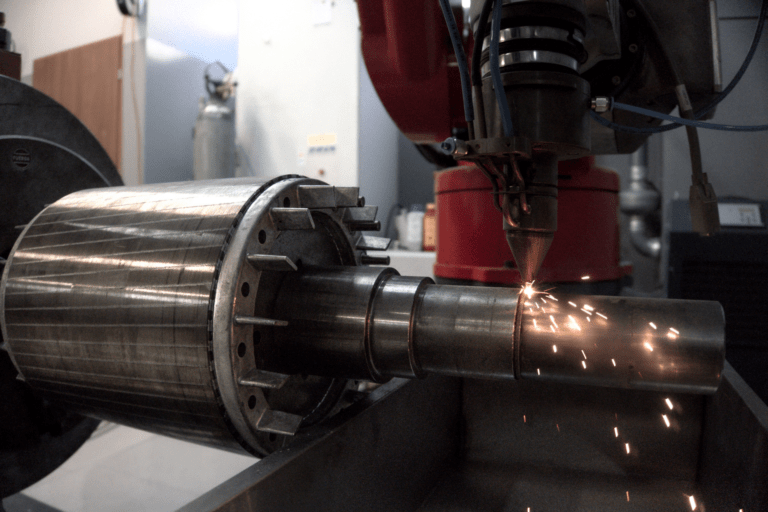

LASER CLADDING

Utilizing advanced Coaxial process heads and high-quality metallic powders, we offer rapid and precise laser cladding based on 3D model data. We also perform cladding on shaft surfaces.

LASER WELDING

Laser welding enables the joining of materials using a laser beam without the need for additional material. This process allows for distortion-free joining with minimal heat input.