Machining and modifications

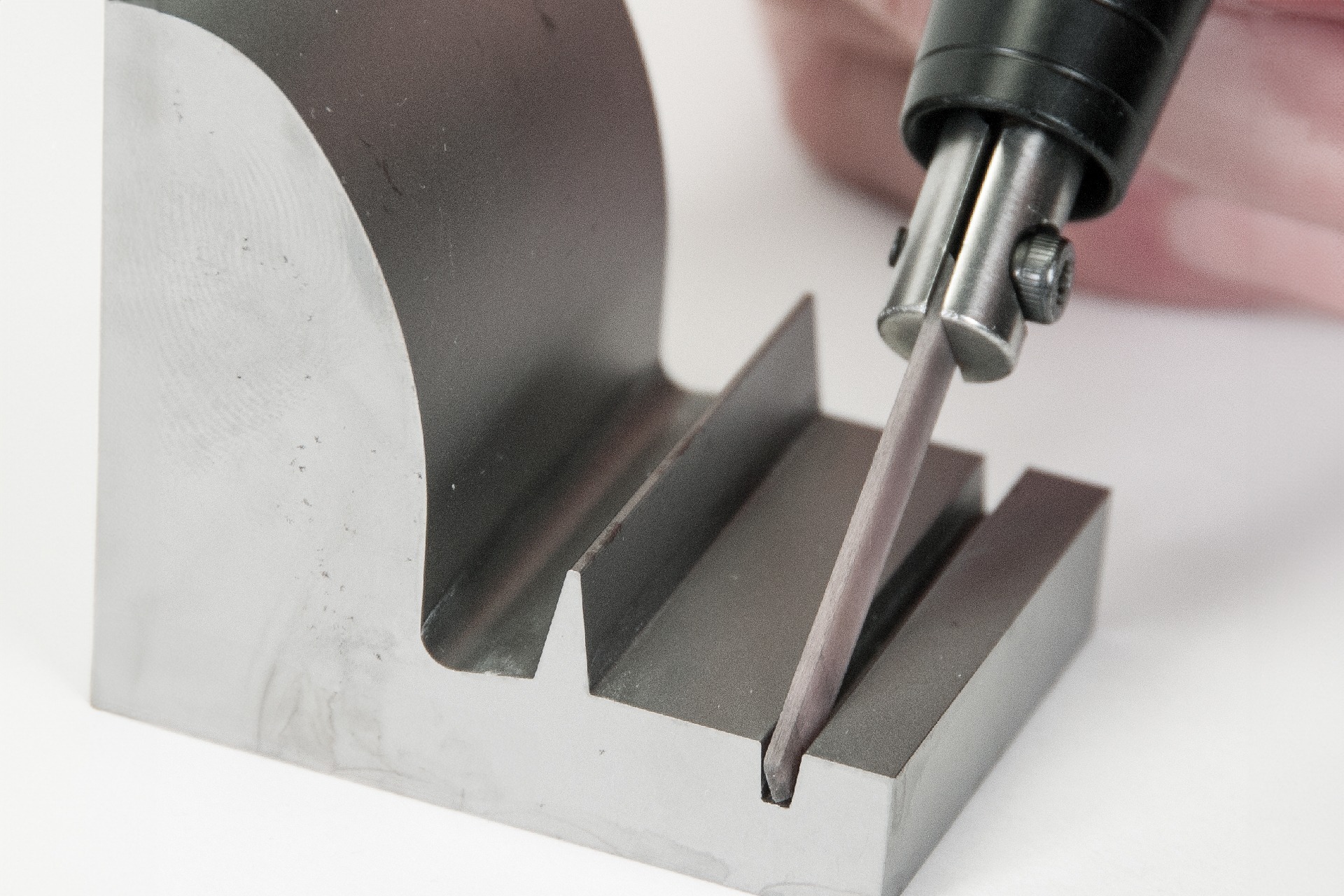

Our service offering includes not only laser welding and engraving services but also repairs and modifications of injection molds based on both 3D files and direct guidelines from the client in case of lack of documentation. We repair, reproduce, or re-manufacture damaged inserts, sliders, ejector pins, and other components of injection molds.

LASERPOINT SERVICES RANGE

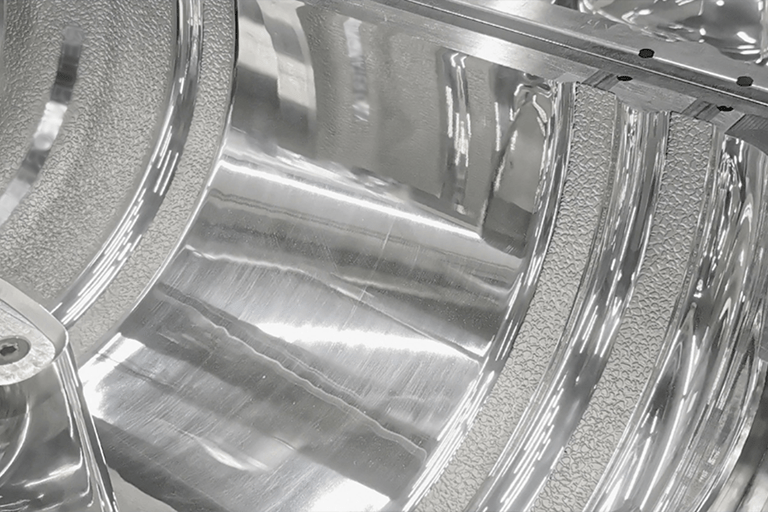

1. We polish forming surfaces to remove traces of previous mechanical processing, reducing roughness for easier mold release and achieving a perfect aesthetic finish with “high gloss” polishing.

2. We regenerate closures to remove plastic flash, weld and process damages even on polished surfaces, restoring impeccable shine to your components.

3. Damage on textured surfaces is also within our capabilities. We weld, process, and then restore damaged structures mechanically and through chemical etching.

All services can be performed at the client’s facility as needed, avoiding costs associated with transporting large tools and significantly reducing unplanned production downtime.

LASERPOINT MACHINE PARK

We execute our work at an express pace, primarily relying on a qualified and experienced team, equipped with: