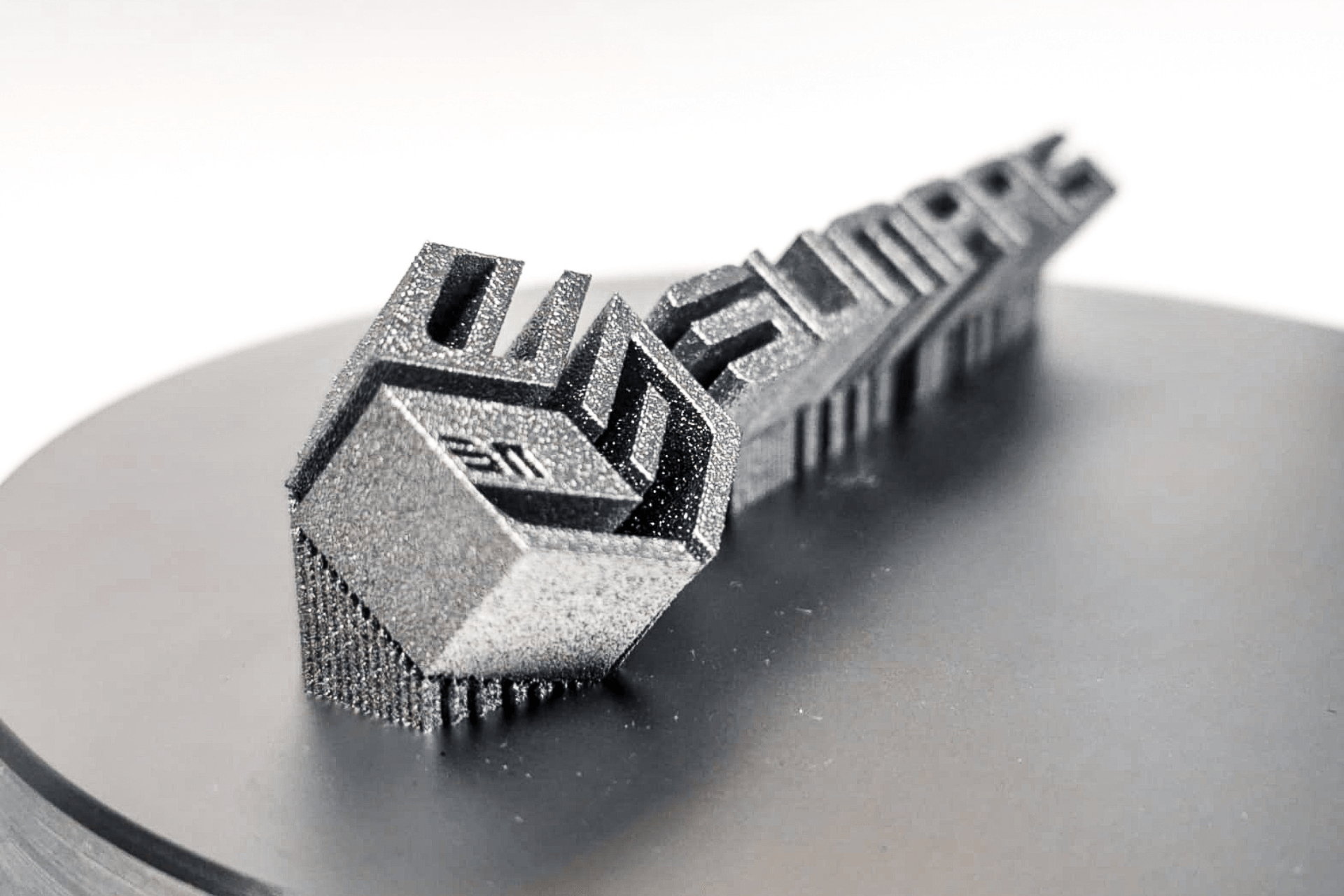

METAL 3D PRINTING SLM SERVICES FOR INDUSTRY

We specialize in providing advanced 3D printing services using SLM (Selective Laser Melting) technology.

3D printing using SLM (Selective Laser Melting) technology

(SELECTIVE LASER MELTING)

finds its applications in industries such as automotive, aviation, medicine, and precision engineering technologies. This method is also used in Rapid Prototyping and Rapid Tooling processes. We ensure that our offerings are optimally tailored to the needs of customers seeking high-quality prototype machine elements, parts impossible to produce by traditional methods, and components manufactured through Reverse Engineering processes.

Key Benefits of Choosing Laserpoint

TECHNOLOGY

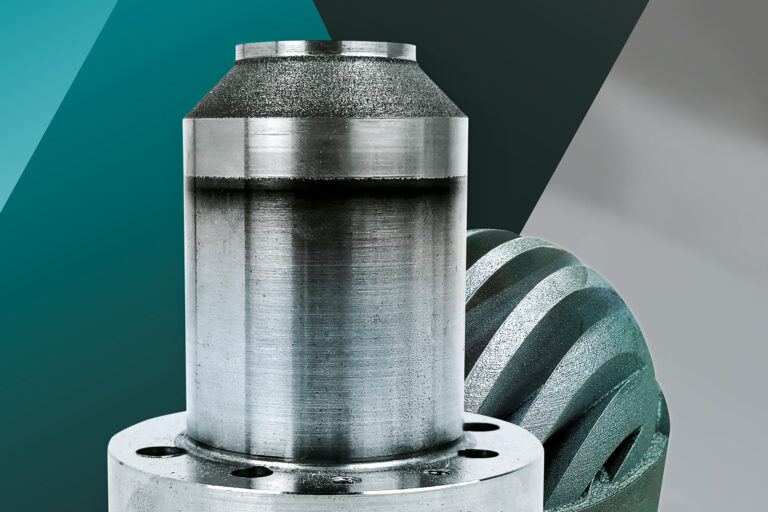

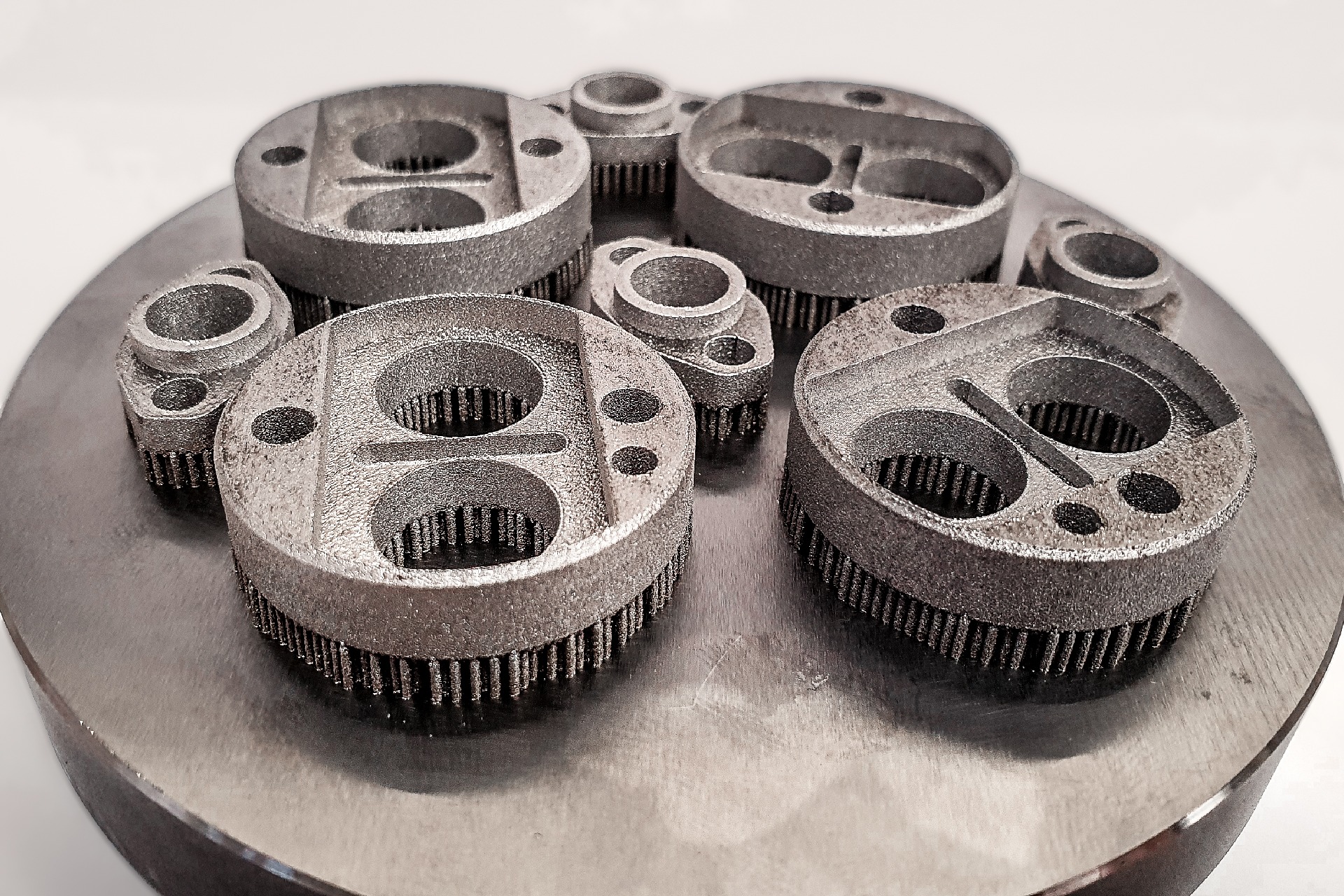

The use of SLM technology enables fast and cost-effective 3D printing of small components, with the ability to work within a working area of diameter and height of 100mm.

SUPPORT

We employ experienced engineers specializing in optimizing projects for 3D printing, ready to support the client at every stage of design.

POST-PROCESSING

We offer comprehensive post-processing, including machining, welding, and anodizing. Clients receive finished products ready for use.

COMPREHENSIVENESS

We utilize a wide range of materials, including stainless steel alloys (e.g., stainless steel 316L, 17-4PH, tool steel 1.2709, maraging C 300), titanium alloys, aluminum, and other specialized alloy powders.

QUALITY

Highest standards of workmanship are our priority. In addition to the products themselves, semifinished products, or final products, our management methodology is crucial. Our ISO 9001 certification confirms our commitment to quality management in both production and other departments.

Just in Time

The delivery time depends on the type of order. Nevertheless, our experience and established working methods allow us to finalize projects within as little as 5 working days, consistently ensuring the highest quality and precision.

WORKING AREA

The printing chamber with a diameter and height of 100mm allows for fulfilling orders of individual items without the need to fill a large working space, minimising costs. This translates into the ability to provide services to smaller businesses and individual clients.

WORKING AREA

The printing chamber with a diameter and height of 100mm allows for fulfilling orders of individual items without the need to fill a large working space, minimising costs. This translates into the ability to provide services to smaller businesses and individual clients.

MATERIALS AVAILABLE FOR PRINTING

TITANIUM

(Ti-6Al-4V)

ALUMINUM

(AISi10Mg)

STAINLESS STEEL

(17-4PH, 316L)

TOOL STEEL

(1.2709, maraging C 300)

COBALT ALLOYS

(Co Alloys)

CHROMIUM ALLOYS

(Cr Alloys)