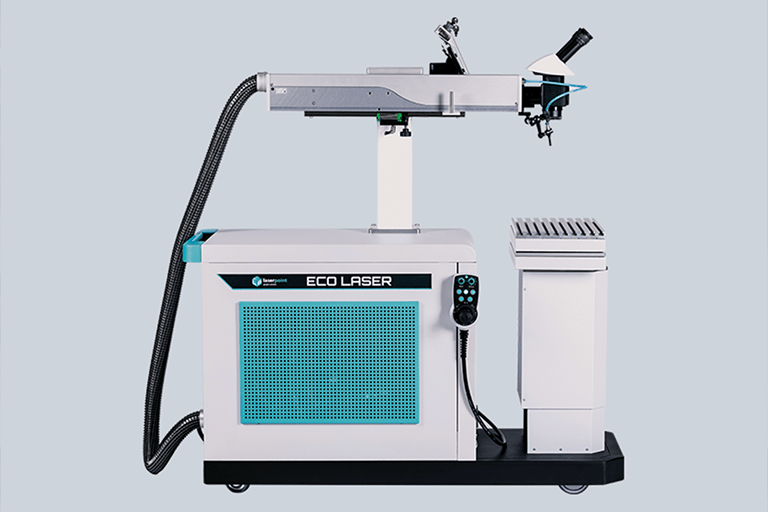

ECO Laser Welder

The ECO laser welder is a device designed for processing small series and individual parts, such as tools and molds, with a weight of up to 120 kg. The ECO welder is successfully used in various fields, including automotive, electronics, medical, jewelry, machinery, mold and tool construction, and the aerospace industry.

-

01.LIQUID COOLING SYSTEM

ensures long-lasting and stable operation

-

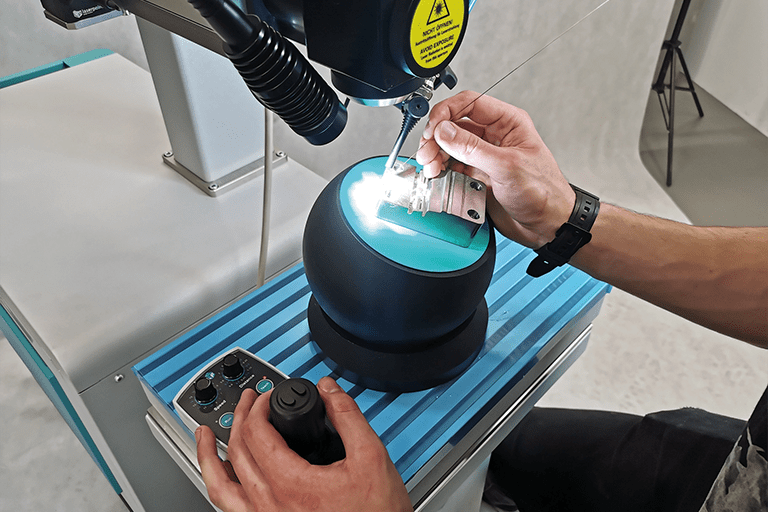

02.JOYSTICK

a digital-analog joystick allowing smooth control of movement in three axes plus rotational. Includes Teach-In function, feed synchronization (0.05 – 3 mm), and intuitive welding path programming function.

-

03.WORK TABLE

adjustable in height, allowing precise handling of the workpiece

-

04.ADJUSTABLE NOZZLE

ensures stable gas flow within the welding area

-

05.LEICA BINOCULARS

high-quality binoculars with 10x or 16x magnification for precise welding position adjustment with accuracy up to 0.01mm

-

06.TOUCH INTERFACE

provides intuitive control over machine operating parameters and access to additional software functions

-

07.SLIDE-TILT RESONATOR MOUNTING SYSTEM

allows setting the angle of the laser beam and additional mechanical movement in the X axis

-

08.BASE WITH 2 SWIVEL WHEELS

enables quick and effortless movement of the laser system

Reasons to choose ECO

Design

ECO is designed with operator efficiency in mind. Its open design allows for easy manipulation of the workpiece, and the work table control function streamlines the welding process.

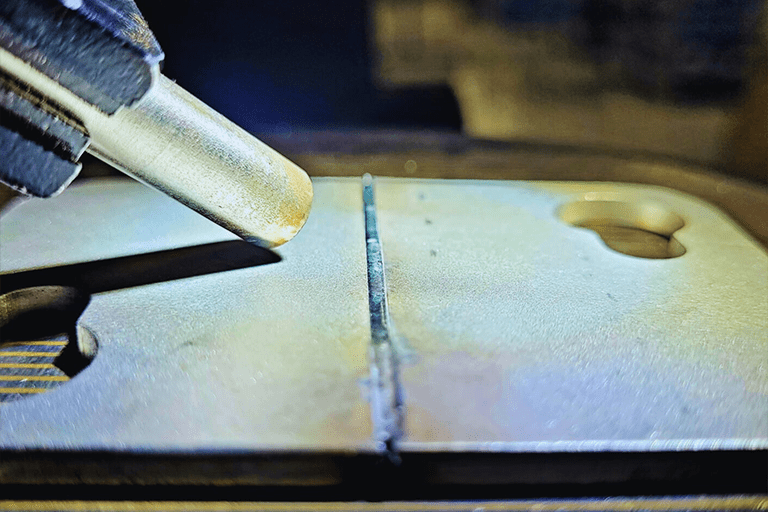

VERSATILITY

ECO is suitable for working with all materials available on the market, including steel, bronze, precious metals, nitrided steel, and other hard-to-machine metals.

FLEXIBILITY

The size and mobility of ECO allow for the installation of the welder even in small workspaces.

ECO WELDER IN A NUTSHELL

Motorized feed in X / Y / Z axes and rotational axis R (in this case, the device should be equipped with an additional element – the Motorized Rotary-Tilt Holder)

Ergonomic Joystick and Intuitive Touchscreen Interface

Teach-In Function: Easy operation and user customization

Direct Laser beam generation source (Nd:YAG)

Repositionable Resonator with Multi-Stage Tilt Function

Integrated Water-Air Cooling System

Automated Work Table with a Load Capacity of up to 120 kg

Available variants

| Specification | ECO ONE | ECO 160 | ECO 200 |

|---|---|---|---|

| Laser type | Nd: YAG | Nd: YAG | Nd: YAG |

| Max. mean power | 110W | 160W | 200W |

| Pulse peak power | 6 kW | 9 kW | 11 kW |

| Max. pulse energy | 70 J | 100 J | 120 J |

| Pulse duration | 0,2 - 20 ms | 0,2 - 20 ms | 0,2 - 20 ms |

| Pulse frequency | 0,5 - 20 Hz | 0,5 - 20 Hz | 0,5 - 20 Hz |

| Focus diameter | 0,03 - 2,00 mm | 0,03 - 2,00 mm | 0,03 - 2,00 mm |

| Line voltage (V/Ph/Hz) | 230 V / 1 Phase | 380 - 420 V AC / 3 Phases | 380 - 420 V AC / 3 Phases |

specification

Linear System

Motorized X/Y/Z axes driven by stepper motors, operated via joystick.

Maximum feed speed: (digital mode | analog mode)

- X and Y axes (3.7 mm/s | 3.7 mm/s)

- Z axis (9 mm/s | 9 mm/s)

Minimum feed speed: (digital mode | analog mode)

- X and Y axes (0.10 mm/s | 0.065 mm/s)

- Z axis (0.38 mm/s | 0.25 mm/s)

Travel:

- Y axis 210 mm / X axis 90 mm / Z axis 300 mm

Technology and equipment

- Tilting and Sliding Laser resonator

- Nd:YAG crystal laser source

- Interface with control and system monitoring functions

- Control panel for adjusting machine parameters, including power, width, and pulse frequency

- Efficient internal water-air cooling system with the option to connect an external cooling system

- Shielding gas supply controlled by electromagnetic valve

Components of laser optics

- Binoculars 10x (Leica), Welding spot size regulator, Directional mirror, Focusing lens, Protective glass, LCD protective shutter

Dimensions and weight

- width 472mm x height 1270mm x length 1160mm

- 190 kg net

specification

Linear System

Motorized X/Y/Z axes driven by stepper motors, operated via joystick.

Maximum feed speed: (digital mode | analog mode)

- X and Y axes (3.7 mm/s | 3.7 mm/s)

- Z axis (9 mm/s | 9 mm/s)

Minimum feed speed: (digital mode | analog mode)

- X and Y axes (0.10 mm/s | 0.065 mm/s)

- Z axis (0.38 mm/s | 0.25 mm/s)

Travel:

- Y axis 210 mm / X axis 90 mm / Z axis 300 mm

Technology and equipment

- Tilting and Sliding Laser resonator

- Nd:YAG crystal laser source

- Interface with control and system monitoring functions

- Control panel for adjusting machine parameters, including power, width, and pulse frequency

- Efficient internal water-air cooling system with the option to connect an external cooling system

- Shielding gas supply controlled by electromagnetic valve

Components of laser optics

- Binoculars 10x (Leica), Welding spot size regulator, Directional mirror, Focusing lens, Protective glass, LCD protective shutter

Dimensions and weight

- width 472mm x height 1270mm x length 1160mm

- 190 kg net